E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

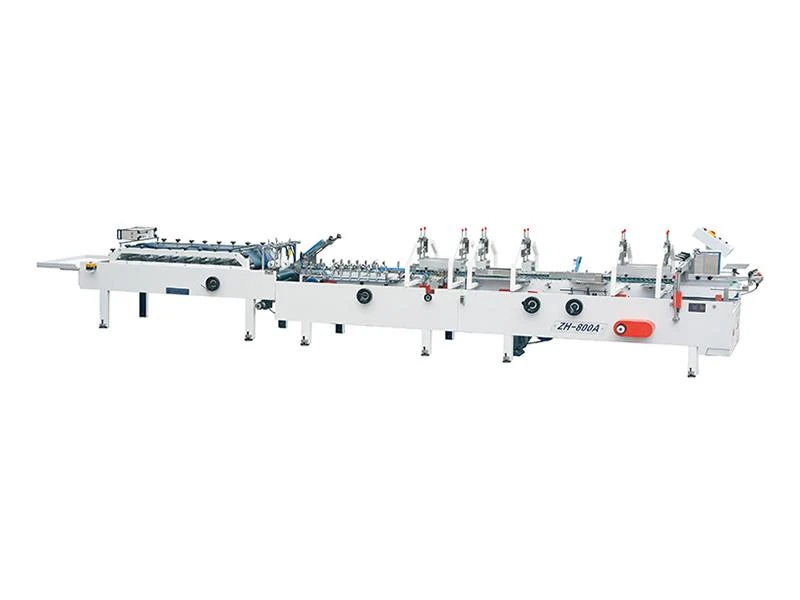

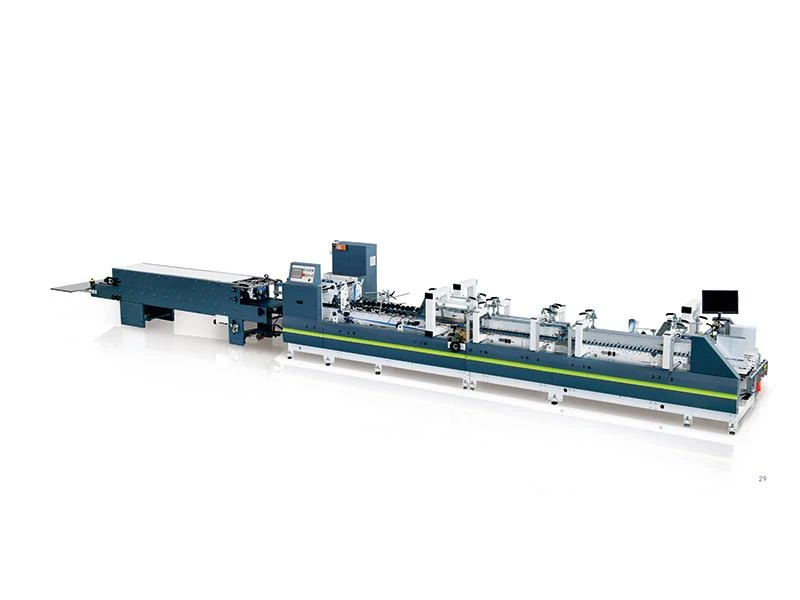

Auto folder gluer machines, while efficient, can encounter various operational hiccups that disrupt production. This article delves into diagnosing and resolving these issues based on expert guides, emphasizing practical, step-by-step approaches to restore functionality. By understanding root causes and implementing fixes, operators can minimize downtime and extend the automatic gluing machine life. Printing and packaging machinery companies like EX.EXPORT offer robust models designed with ease of maintenance in mind, helping businesses avoid frequent problems.

Troubleshooting begins with identifying prevalent issues, which often stem from material incompatibilities, mechanical wear, or operational oversights. For instance, inaccurate folds, gaps, or misplaced creases frequently arise from the paper or cardboard's composition, such as variations in fiber density or surface finishes that affect how the material interacts with rollers and fold plates. Upstream processes, like overloading the feeder tray, can exacerbate this, leading to inconsistent feeding and alignment errors. Worn-out conveyor belts or misaligned components further compound the problem, causing the auto folder gluer machine to produce defective boxes that buckle or fail during use.

Another common challenge is slow or inconsistent speed, often due to neglected maintenance, such as unlubricated gears or accumulated debris in drive systems. This not only reduces output but can lead to uneven gluing, where adhesive bonds weaken because of improper application timing. Weak adhesive issues typically trace back to poor glue quality or environmental factors like humidity affecting viscosity, resulting in seams that peel apart under stress.

Paper jams represent a frequent frustration, caused by substrates that are oversized or undersized for the auto folder gluer machine's settings, misaligned conveyors, or bent fold plate deflectors. In high-speed operations, thin papers may curl at edges due to rapid roller passes or folds against the grain, creating inconsistent curls that jam the process. Multiple sheets feeding at once often occurs from static cling in the tray, especially during continuous runs.

Mechanical and electrical problems add layers of complexity. Belt slippage arises from improper tension or damage, disrupting carton movement, while gear and bearing wear produces excessive noise and vibration from prolonged use without lubrication. Electrical surges can damage sensors, leading to malfunctions in detection systems that control folding accuracy. In flexo folder gluers, misregistration and print alignment errors stem from plate slippage or web tension variations, while slotting misalignment results from worn knives or poor anvil conditions. Carton interlocking jams are linked to flap snags or excessive shingle pitch overlap.

Scorching or burning of corrugated board indicates overheating elements or slow speeds allowing prolonged exposure. Poor glue application might involve clogged nozzles or insufficient tank levels, while sensor malfunctions from dust buildup cause incorrect operations. These causes highlight the interconnected nature of auto folder gluer machine components, where one fault can cascade into others, underscoring the need for holistic diagnostics. Observing behavior, listening for noises, and checking indicators are initial steps before delving deeper.

Once issues are diagnosed, targeted repairs can restore efficiency. For inaccurate folds, test with alternative substrates to isolate material problems; if persistent, halt operations and replace worn belts or realign conveyors using manufacturer guides. Step-by-step: Measure belt tension with gauges, adjust via tension mechanisms, and run test sheets to verify.

To address slow speeds, conduct a full maintenance check: Lubricate gears, clean debris from electrical cabinets, and inspect for underlying faults like faulty encoders. For weak adhesive, switch to higher-strength glue or install grinding devices; balance pump pressure per specs, test bond strength on sample sheets, and record settings for future jobs.

Paper jams require verifying substrate dimensions first, then realigning conveyors and fold plates with straightedges or measuring tools. Replace bent deflectors by contacting suppliers for parts; clean paths with compressed air. For curling edges, widen feeder gaps or install guides and smoothers; flip sheets to align with grain, testing incrementally.

Multiple sheet feeding can be temporarily fixed by manually fanning edges, but install suction devices for long-term resolution. Belt slippage involves adjusting tension and replacing damaged belts—keep spares handy. For gear wear, lubricate per OEM intervals and replace bearings if vibration persists.

In flexo models, fix misregistration by maintaining web tension, greasing rolls, and using test runs with cross-lines to adjust timing. Glue over-application needs nozzle cleaning and viscosity matching with heaters; slotting issues call for knife rotation or anvil resurfacing, confirmed with gauges.

For scorching, reduce heating temperatures, increase speed, and ensure flat boards; replace elements as needed. Excessive noise demands tightening loose bolts, lubricating parts, and inspecting drives. Electrical fixes include surge protectors and sensor cleaning; check wiring and replace faulty units.

Poor glue application: Refill tanks, verify pumps, unclog nozzles with brushes, and adjust settings for material. Misaligned folders: Use straightedges for guides, clean buildup. Always document repairs in logs for patterns. If issues exceed in-house expertise, consult auto folder gluer machine professionals like those at EX.EXPORT for diagnostics and parts. Safe practices: Power off before repairs, use PPE. These steps, when followed meticulously, can reduce downtime by up to 50% in packaging lines.

Prevention is key to avoiding costly repairs, starting with regular cleaning to remove paper scraps, glue residue, and dust from surfaces, internals, nozzles, and sensors. Use mild solvents for rollers and compressed air for paths; schedule daily post-operation cleanings.

Inspect components weekly: Check drive systems, lubrication points, belts for fraying, anvils for wear, and electrical cabinets for debris. Lubricate gears, chains, and bearings per manuals, replacing oil and filters routinely. Calibrate auto folder gluer machines regularly for alignment and settings.

Operator training enhances prevention—teach identification of early signs like unusual noises or vibrations, and proper SOPs for loading and speed adjustments. Use checklists for inspections, tracking vibration with tools for early detection.

For flexo models, maintain web tension and clean nozzles daily; store job recipes in HMIs for consistent setups. Install smart sensors to detect jams proactively, pausing feeds automatically.

Electrical safeguards include surge protectors and grounding; keep spares like belts and knives on hand. Adhere to safety protocols: Train on emergency stops, avoid operation during faults, and prioritize grounding.

Integrate preventive strategies into workflows, like design reviews to minimize interlocking risks and bypass plans for high-risk jobs. Regular training boosts skills, reducing errors. By following these practices, automatic folder gluer machines can operate smoothly for years, as seen in facilities using reliable printing and packaging equipment from providers like EX.EXPORT. Ultimately, a proactive approach not only extends lifespan but also optimizes production, ensuring high-quality output with minimal interruptions.

Hello, I am Valerie Xu. With over a decade in the global printing and packaging industry, I connect clients with top-tier Chinese manufacturing solutions. My expertise allows me to source, customize, and deliver high-performance equipment worldwide.

I turn your machinery investment into a strategic advantage by identifying the best equipment for your needs and budget. My services include:

✅ Pre-Sales: Consultations, factory audits, and equipment matching.

✅ After-Sales: Installation, training, maintenance, and spare parts.

I streamline purchasing, mitigate risks, and optimize costs, ensuring a trusted partnership for success. Let’s elevate your operations with precision-engineered solutions.