E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

For businesses seeking to produce high-quality printed materials, whether it's business cards, brochures, or custom products, understanding the commercial printing process is crucial. Knowing the various stages involved, from design to final delivery, will help you manage expectations and ensure your final product meets the highest quality standards.

The commercial printing process refers to the steps involved in transforming a design into a finished printed product. From initial design to final delivery, each stage plays a vital role in ensuring the quality and accuracy of your printed materials. It's more than just a simple "printing" procedure; it's a complex system involving multiple intricate steps. Understanding these steps allows businesses to better control costs, shorten turnaround times, and ultimately achieve satisfactory printing results.

We've broken down the commercial printing process into three main stages: Pre-Press, Press, and Post-Press. Each stage has its unique processes and technical requirements.

The pre-press stage is the foundation of the entire printing process. Its core task is to thoroughly prepare for the subsequent printing phases. If printing is akin to building a house, then pre-press is laying the foundation. The quality of work in this stage directly impacts the quality of the final printed product.

Design File Preparation: Ensuring all design files (including text, images, graphics, etc.) are in the correct format and meet resolution standards. This often involves using professional typesetting software (like Adobe InDesign) and image processing software (like Adobe Photoshop).

Color Management: Commercial printing demands high color fidelity. The pre-press stage requires color correction and management to ensure the colors on the printed product match the colors in the design as closely as possible.

Font Handling: Ensuring that all used fonts are either embedded or converted to outlines to avoid printing errors due to missing fonts.

Imposition and RIP: Imposition refers to arranging multiple pages or elements on a printing plate according to specific rules to facilitate printing and subsequent processing. RIP (Raster Image Processor) is a process that converts vector graphics and text into raster images that can be recognized by the printing press.

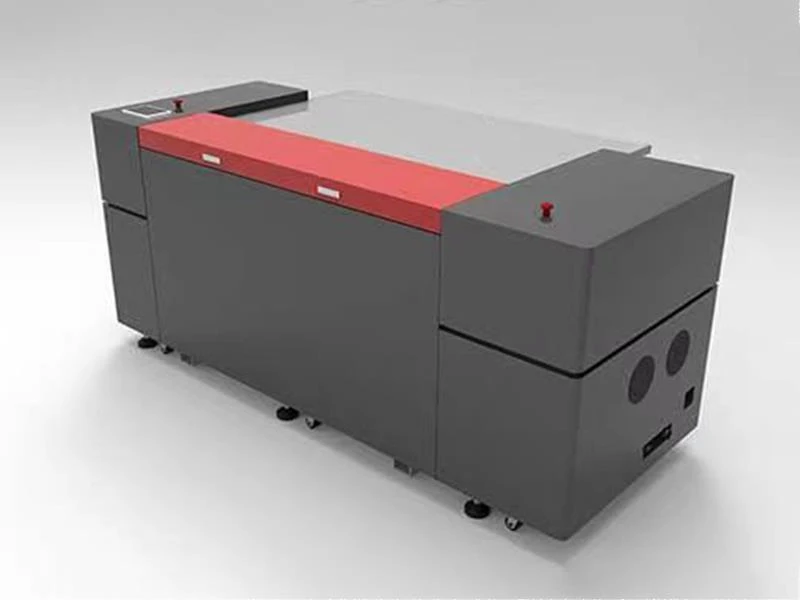

Platemaking: Choosing the appropriate platemaking process based on the printing method (e.g., offset, flexo). For example, CTP (Computer-to-Plate) technology has become the mainstream for modern offset platemaking. Using EX.Export’s DX660F CTP flexo plate making machine can complete platemaking efficiently and with high precision. For more prepress equipment for sale options, you can contact us at any time.

The press stage is the core of the commercial printing process, where the prepared graphic information from the pre-press stage is transferred onto the substrate (e.g., paper, plastic, etc.).

Printing Method Selection: Choosing the appropriate printing method based on factors such as the type of printed material, quantity, quality requirements, and budget. Common printing methods include:

Offset Printing: One of the most widely used printing methods, suitable for large-volume, high-quality printed materials such as books, magazines, posters, etc.

Digital Printing: Digital printing offers high flexibility, variable data printing, and eliminates the need for platemaking, making it suitable for small-volume, personalized printed materials like business cards, flyers, variable QR code printing, etc.

Flexographic Printing: Flexographic printing is suitable for packaging printing, such as cardboard boxes, plastic bags, labels, etc.

Screen Printing: Screen printing is suitable for printing on special materials such as textiles, glass, metal, etc.

Printing Process Control: During the printing process, it's crucial to strictly control parameters such as ink density, printing pressure, and registration accuracy to ensure the quality of the printed product. Choosing the right printing equipment is essential. EX.Export offers a variety of printing equipment, such as Offset Printing Machines, Flexo Printing Machines, Screen Printing Machines, and Label Printing Machines, to meet your different needs.

Quality Inspection: Conducting quality inspections during the printing process to promptly identify and correct issues.

| Offset Printing Machine |  |

| Flexo Printing Machine |  |

| Screen Printing Machin |  |

| Label Printing Machine |  |

The post-press stage involves processing and handling printed materials to enhance their quality, aesthetics, and functionality.

Surface Treatment: Common surface treatment processes include lamination, varnishing, UV coating, etc. These processes can improve the abrasion resistance and water resistance of printed products and increase their gloss.

Die Cutting: Die cutting involves using a die to cut printed materials into specific shapes. Die cutting is widely used in packaging printing, label printing, and other fields. EX.Export's auto die cutting machine can help you complete die cutting efficiently.

Binding: Binding is the process of securing multiple pages or single sheets of paper together. Common binding methods include saddle stitching, perfect binding, case binding, etc.

Folding: Folding involves folding printed materials into booklets or other shapes according to specific rules.

Gluing: Gluing is the process of folding cardboard or corrugated board into a box shape and adhering it with glue. For more post press machine options, you can EX.Export at any time.

To ensure a smooth commercial printing process, businesses need to maintain close communication with the printing service provider and pay attention to detail at every stage.

Clear Requirements Communication: Before the project starts, fully communicate your needs to the printing service provider, including the type of printed material, quantity, quality requirements, delivery time, etc.

Strict Quality Control: Conduct quality control at every stage to ensure the quality of the printed product meets your requirements.

Timely Feedback: Provide timely feedback to the printing service provider so they can take corrective measures promptly.

Ready to start your commercial printing project? Contact us today to learn more about how we can help you through every stage of the printing process, from prepress to delivery. With over 20 years of industry experience, EX.Export can provide you with professional printing and packaging equipment and comprehensive service support. Our goal is to help you improve production efficiency, reduce costs, and obtain high-quality printed materials.

Hello, I am Valerie Xu. With over a decade in the global printing and packaging industry, I connect clients with top-tier Chinese manufacturing solutions. My expertise allows me to source, customize, and deliver high-performance equipment worldwide.

I turn your machinery investment into a strategic advantage by identifying the best equipment for your needs and budget. My services include:

✅ Pre-Sales: Consultations, factory audits, and equipment matching.

✅ After-Sales: Installation, training, maintenance, and spare parts.

I streamline purchasing, mitigate risks, and optimize costs, ensuring a trusted partnership for success. Let’s elevate your operations with precision-engineered solutions.