E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

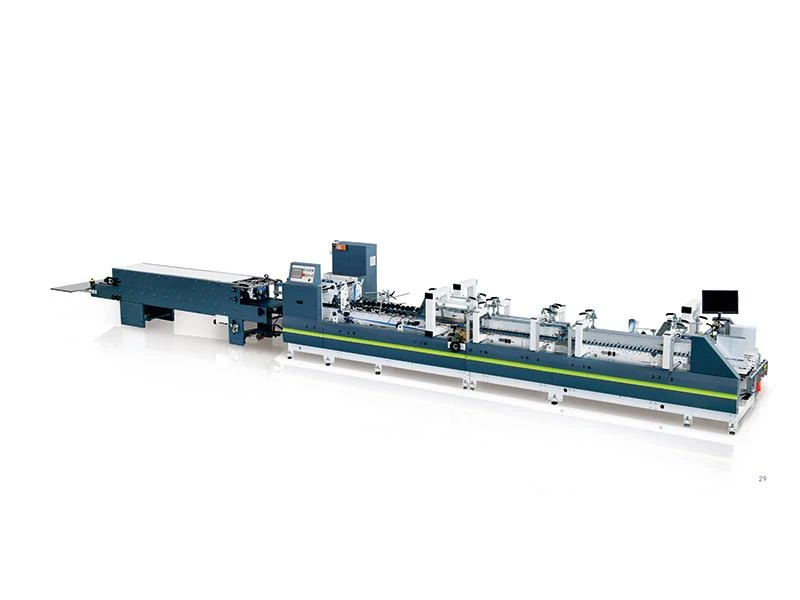

In the fast-paced world of packaging, selecting the right automatic folder gluer machine can make or break operational efficiency. These machines automate the folding, gluing, and pressing of cardboard sheets into boxes, ensuring precision and consistency. For businesses facing delays in packaging, EX.EXPORT offers a solution with their range of automatic folder gluers, designed to eliminate setbacks and enhance productivity. With over 20 years of experience in printing and packaging equipment, EX.EXPORT specializes in exporting high-quality machines like the EX-800 series, which handles cardboard from 200-800gsm and corrugated paper types N/E/F at speeds up to 350 m/min. This guide explores key considerations, helping you make an informed choice while spotlighting how EX.EXPORT's products stand out.

Auto folder gluer machines are engineered to take flat cardboard or corrugated sheets and form them into functional boxes through precise folding and adhesive application. This process is vital for industries producing packaging for medicines, e-commerce items, groceries, electronics, bakery goods, and clothing. Inaccuracies in folding or gluing can lead to box failures, such as improper closure or buckling during shipping, resulting in product damage and increased costs. EX.EXPORT addresses this with models like the ZH-500 Mini Automatic Folder Gluer, a compact unit weighing 600KG and operating at 0-150m/min, ideal for small workshops needing reliable single or double-side gluing on 210-500 g/m paperboard or N/F/E corrugated.

The core components include feeding systems for automatic sheet intake, folding tracks to shape the material, glue applicators for secure bonds, and pressing units to solidify the structure. Modern advancements incorporate intelligent controls for quick adjustments, reducing setup time from hours to minutes. For instance, EX.EXPORT's EXM-1100 series features a Speedwave structure for 4 & 6 corner boxes at 450 m/min, powered by 23.5-25KW, making it suitable for high-volume operations. Businesses benefit from reduced labor strain, as these machines handle repetitive tasks, allowing staff to focus on quality control.

Choosing the type depends on your business scale and production volume. Manual models suit low-volume setups but require more operator involvement, leading to potential errors. Semi-automatic options provide a cost-effective middle ground, with partial automation for moderate speeds. Fully automatic machines excel in large factories, offering high throughput with minimal intervention.

EX.EXPORT's lineup includes versatile series like the EX-900/1100, reaching 400 m/min with 14KW power, perfect for medium to large enterprises. For specialized needs, the EXBR-650/850 Full Automatic Braille Machine automates Braille-printed sheets, crucial for institutions serving the visually impaired. Consider applications: e-commerce demands sturdy shipping boxes, while food packaging requires hygienic, precise gluing to prevent contamination.

| Type | Best For | Key EX.EXPORT Model | Speed (m/min) | Power (KW) |

|---|---|---|---|---|

| Manual | Small workshops | ZH-800 | 0-220 | 3 |

| Semi-Automatic | Growing businesses | ZH-A Series | 0-220 | 4.5 |

| Fully Automatic | Large factories | EX-800 I | 350 | 9 |

This table highlights how EX.EXPORT's models align with needs, emphasizing durability with weights from 4T to 7.6T.

Focus on features that enhance performance and safety. Speed and capacity should match your output—EX.EXPORT's EXN-1200 series delivers 400 m/min for corrugated boxes, with automatic feeding to prevent bottlenecks. Material compatibility is essential; machines must handle recycled cardboard without jams, supporting sustainability goals.

Advanced features include AI-driven adjustments for material detection, reducing errors by up to 50%. EX.EXPORT integrates these in their ZH-D Series, with crash lock bottom capabilities for complex boxes. Safety elements like protective covers and emergency stops are standard, as in the ZH-G Series with multi-functional gluing. Ease of adjustment via digital interfaces minimizes downtime, a hallmark of EX.EXPORT's high-configuration designs.

Build quality ensures longevity; EX.EXPORT uses premium materials for machines lasting decades, backed by 99% customer satisfaction and 100% on-time delivery.

Evaluate how the machine processes materials like single-wall for standard boxes or double-wall for heavy items. EX.EXPORT's models accommodate 200-800gsm cardboard and N/E/F corrugated, ideal for variable suppliers. Workspace factors include noise levels—quieter operations suit shared spaces—and energy efficiency, with EX.EXPORT's 220V/380V options optimizing costs.

Dimensions matter: the ZH-500 measures 2600x660x1112mm, fitting compact areas, while larger units like the EXM-1100 at 7.3T require ample space.

Reliable suppliers provide manuals, parts, and service. EX.EXPORT, based in Shanghai, offers one-stop solutions with extensive experience in post-press equipment. Maintenance involves cleaning nozzles and lubricating parts to avoid issues.

Cost-benefit analysis shows initial investments recouped through efficiency gains. For example, a case study from a packaging firm reported 50% speed increases after adopting similar machines. EX.EXPORT's competitive pricing and customization drive ROI.

Assess production needs, test demos, and prioritize versatility. EX.EXPORT encourages inquiries for tailored advice—click "Learn More Inquire" on models like the EX-800.

What speed do I need? Match to volume; EX.EXPORT offers up to 450 m/min.

Can it handle recycled materials? Yes, with adjustments for quality variations.

How does EX.EXPORT ensure quality? Through 20+ years of expertise and high satisfaction rates.

Selecting an EX.EXPORT machine transforms packaging—get a quote today to explore how their solutions fit your business.

Hello, I am Valerie Xu. With over a decade in the global printing and packaging industry, I connect clients with top-tier Chinese manufacturing solutions. My expertise allows me to source, customize, and deliver high-performance equipment worldwide.

I turn your machinery investment into a strategic advantage by identifying the best equipment for your needs and budget. My services include:

✅ Pre-Sales: Consultations, factory audits, and equipment matching.

✅ After-Sales: Installation, training, maintenance, and spare parts.

I streamline purchasing, mitigate risks, and optimize costs, ensuring a trusted partnership for success. Let’s elevate your operations with precision-engineered solutions.