E-mail:

exexportmachinery@126.com

Tel:

+86-15256547590

Die cutting machines are essential tools in various industries, designed to cut materials into specific shapes with high precision and efficiency. From paper and fabric to rubber, foil, foam, and even sheet metal, these machines have revolutionized manufacturing processes. In this blog, we will explore the diverse applications of industrial die cutting machines, focusing on the benefits of using automatic die cutters, including automatic rotary die cutting machines and automatic flatbed die cutting machines. We will also highlight the offerings from EX.EXPORT automatic die cutting machine factory, which provides a range of printing and packaging equipment for your unique applications.

Die cutting machines have come a long way since their inception in the mid-19th century, when they were initially designed to cut leather for shoes. Today, this post press equipment is used in a wide range of industries, from packaging to automotive manufacturing, and beyond. The advancements in technology have led to the development of various types of die cutting machines, including manual, semi-automatic, and fully automatic die cutters.

Get Die Cutting Machines Quote

1. Cardboard and Carton Packaging

One of the most common uses of die cutting machines is in the packaging industry. Die-cut cardboard and fiberboard are used to create a variety of packaging supplies, including product packaging, envelope mailers, bookends, and cargo liner components. The precision and efficiency of automatic die cutters make them ideal for producing high-quality packaging materials.

2. Foam Parts

Die cutting machines are capable of processing foam, which is used in various applications such as rigid foam insulation, automotive parts, and gaskets. The ability to cut foam with high precision makes automatic die cutters indispensable in industries that require custom foam parts.

3. Plastic Parts

Some die cutting machines can process thin sheets of plastic, which are used to create an array of products. Plastics manufacturers often use automatic die cutters to fabricate stiffeners, hold-downs, and other plastic components. The versatility of these machines allows for the efficient production of high-quality plastic parts.

4. Rubber Parts

Die-cut rubber is extensively used in the automotive industry to create components such as rubber gaskets and gasoline engine seals. Automatic rotary die cutting machines are particularly well-suited for producing these parts due to their high precision and ability to handle large production volumes.

5. Fabrics and Fibers

Almost all types of fabrics can be die cut, making these machines essential in the textile industry. Die cutting is used to create textiles for furniture-making, interior decor, and clothing design. The ability to cut intricate shapes and patterns with high precision makes automatic flatbed die cutting machines ideal for these applications.

When choosing a die cutting machine, industrial business owners must decide between manual and automatic options. While manual die cutters are still used in some industries, advances in digital technologies have made automatic die cutters more popular due to their efficiency and precision.

Get Manual Creasing and Die Cutting Machine Quote

Inquire about Automatic Die Cutting And Creasing Machine

Manual die cutters work like large-scale cookie cutters, using prefabricated dies to cut materials into specific shapes. These machines are becoming less common as automatic die cutters offer greater efficiency and versatility. However, manual die cutters are still used in industries such as apparel, packaging, and printing for specific applications.

Check out the ML-750 Manual Die Cutting and Creasing Machine

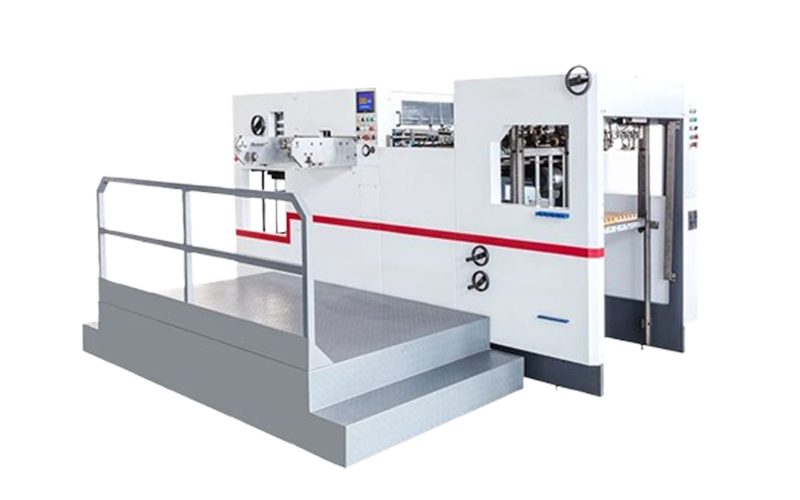

Automatic die cutters, including automatic rotary die cutting machines and automatic flatbed die cutting machines, offer numerous advantages over manual machines. These machines use programmed blades or lasers to cut shapes with high precision and consistency. They are ideal for large-scale production and can handle a wide range of materials.

Check out the EX-800E Automatic Die Cutting And Creasing Machine

Consistency and Uniformity: Automatic die cutters ensure that all shapes are cut uniformly, eliminating variations that can occur with manual cutting.

Speed and Efficiency: These machines can cut shapes much faster than manual die cutters, increasing productivity and reducing labor costs.

Reduced Waste: Automatic die cutters can arrange shapes closely together, minimizing material waste and maximizing efficiency.

Complex Shapes: These machines can easily cut intricate shapes and patterns that would be difficult to achieve with manual cutting.

Versatility: Automatic die cutters can handle a wide range of materials, making them suitable for various industries.

Industrial die cutting machines play a crucial role in various industries, offering precision, efficiency, and versatility. Whether you need to cut cardboard, foam, plastic, rubber, or fabric, there is an automatic die cutter that can meet your needs. By understanding the different applications and advantages of these printing and packaging machines, you can make an informed decision that maximizes productivity and quality in your operations. EX.EXPORT automatic die cutting machine factory provides an extensive selection of die cutting machines tailored to your specific requirements. Whether you need a manual die cutting machine, a semi-automatic die cutting machine, or a fully automatic die cutting machine, EX.EXPORT has the ideal solution for you.

Hello, I am Valerie Xu. With over a decade in the global printing and packaging industry, I connect clients with top-tier Chinese manufacturing solutions. My expertise allows me to source, customize, and deliver high-performance equipment worldwide.

I turn your machinery investment into a strategic advantage by identifying the best equipment for your needs and budget. My services include:

✅ Pre-Sales: Consultations, factory audits, and equipment matching.

✅ After-Sales: Installation, training, maintenance, and spare parts.

I streamline purchasing, mitigate risks, and optimize costs, ensuring a trusted partnership for success. Let’s elevate your operations with precision-engineered solutions.